Fukae Kasei Co., Ltd. utilizes its unique know-how and plastic injection molding technology accumulated in the development of products in the life sciences field, from design to mass production, being a member of your company's staff in the development of products.

For example, we meet the need for cost-reduction of existing plastic products and plastic conversion of Non-Plastic products.

We also offer a total package that requires post-processing, such as filter insertion into products, rack boxes, and refill products. We are willing to spare any technical cooperation during the development of new products. Please consult with us at once.

Pipette Tips |

Micro Tubes |

Containers |

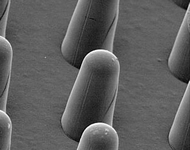

Fine Geometry on Plastic |

Carbon Tips |

Fluororesin Micro Tubes |

Products such as pipette tips, micro tubes, and microplates can be manufactured as genuine products to the machinery developed by your company.

As a merit of a manufacturer with the original brand, in addition to utilizing the unique manufacturing know-how of plastic products for life science fields, for example, by changing only the tip's internal die for the same shape as external die for WATSON products, in some cases, the cost can be reduced while adjusting the fitting. Consult with us about changing the length of tips.

In addition, consult with us about developing bio-devices and OEM products. Problems may be solved by using our unique technologies such as fine geometry on plastic and surface reformation technology. We have successfully developed bio-devices through industry-academia collaboration.

In case of a certain quantity, we believe our proposal would be affordable price and performance. If these custom-made products are intended for mass production, the shape can be checked in the trial manufacture.

Making a shape adapted to the intended use and specification of the client. We will also be a member of your staff and cooperate with you even if it is just an image.

We will review your current products and provide more efficient products.

Plasticizing glass and metal products can improve accuracy and reduce cost.

We are well versed with small items. In particular, we are proud to be able to compete with other companies in the field of microscopic technology. However, please consult with us in case of medium-or large-sized.

By utilizing analytical instruments and collecting data uniquely to select raw materials with consideration for cytotoxicity, with special technologies such as surface hydrophilicity of plastics and surface reforming bonding technology, we will help to solve problems that have been made device development difficult.

We manufacture products in the form as requested by the client. If it is impossible to manufacture because of the characteristics of the molding, we will propose a different method.

In case of plastic, let me try! We have expertise in polypropylene, but biodegradable materials and engineering plastics are possible.

We will create and combine a new customer specified cavity and core part with the base part of our mold. This has enabled us to shorten the mold developing period, reduce the mold manufacturing cost, and verify the performance before mass production.

At the shortest it takes from 1 day to 2 weeks from designing in 3D-CAD to checking shapes on 3D printers. We have established the production system that helps to embody the design and significantly shorten the product development period.

1) Drawing by 3D-CAD

A product drawing is prepared by operators experienced in using 3D-CAD.

2) Formed by 3D printers

3D printers are shaped using special resins on a 3-dimensional CAD-drawn drawing.

3) Shape check

3D printers faithfully shape the objects depicted in the drawings.

※Only in the case of consultation on the premise of mass production.

Fukae Kasei's plastic injection molding technology has been sophisticated to achieve "thinner," "smaller," and "smoother." We are equipped with high-quality technologies that realize the needs of our clients and facilities and production environments that promise stable production.